Steam To Water Heat Exchanger Unit

Order Code: 32286

Category: Thermodynamics Lab

Features Safe and Suitable For Unsupervised Student Operation Responds Rapidly to Control Changes Negligible Operating and Maintenance Costs The Tesca Steam to Water Heat Exchanger Unit has been designed to provide visual a...

SPECIFICATION

Features

- Safe and Suitable For Unsupervised Student

- Operation

- Responds Rapidly to Control Changes

- Negligible Operating and Maintenance Costs

The Tesca Steam to Water Heat Exchanger Unit has been designed to provide visual and quantitative results related to heat transfer in shell and tube type water cooled condensers.

Three interchangeable manifolds allow investigation of single, double or four pass cooling water flow through the condenser tubes.

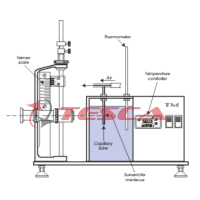

The unit is self-contained and designed for bench top use having its own steam generator and condenser tubes housed in a single thick walled glass cylinder. Instrumentation monitoring the cooling water flow rate, temperature and pressure drop through the tubes allow an interesting and important range of experiments to be conducted. The unit is easily controlled and stabilizes quickly allowing many different conditions to be investigated in a single laboratory period.

Specifications

- Panel: High quality ABS

- Digital Thermometer: Resolution 0.1°C.

- Differential Pressure transducer and Display.

- Flow meters x 2: 10 to 90 cm³ s-1 and 1 to 12 g s-1.

- Pressure Gauge: Range: - 100 to +100 kN/m2.

- Safety Features:

Steam chamber pressure relief valve, pressure

- Switch and heater high temperature cut out.

All electrical components earthed and fuse.

Experiment Possibilities

- Visual demonstration of filmwise condensation and nucleate boiling.

- Demonstration of the increase in heat exchanger effectiveness due to increasing the number of tube passes at constant flow rates.

- Measurement of the effect of coolant flow velocity and the number of tube passes on pressure drop.

- Investigation of the effect of increasing flow velocity and the number of tube passes on the overall heat transfer coefficient.

- Investigation of the saturation pressure/ temperature relationship for H2O at low pressures.

Service Required

- 220V/230V/240V.A.C. stabilized supply with proper earth termination.

- Floor space - 1 m X 1.5m at working height.

- Cold Water supply at the rate of 2 LPM at constant head.

91-9829132777

91-9829132777